CREATE Shop Internship @ Robotics Factory

Quick Release Connectors for Filter Systems

At a Glance

Parametrically design and prototype a fast, tool-free connector system that allows users to quickly attach, detach, and swap BOFA fume-extraction ducts in makerspace and robotics-lab environments.

Why It Matters:

Standard BOFA duct fittings are secure but slow to change, interrupting workflows.

Startups and engineers often reconfigure workstations—rapid duct changes improve safety, flexibility, and productivity.

Reduces wear on existing fittings and minimizes downtime during equipment swaps.

Documented Work in Progress

Joint Mechanism Ideation

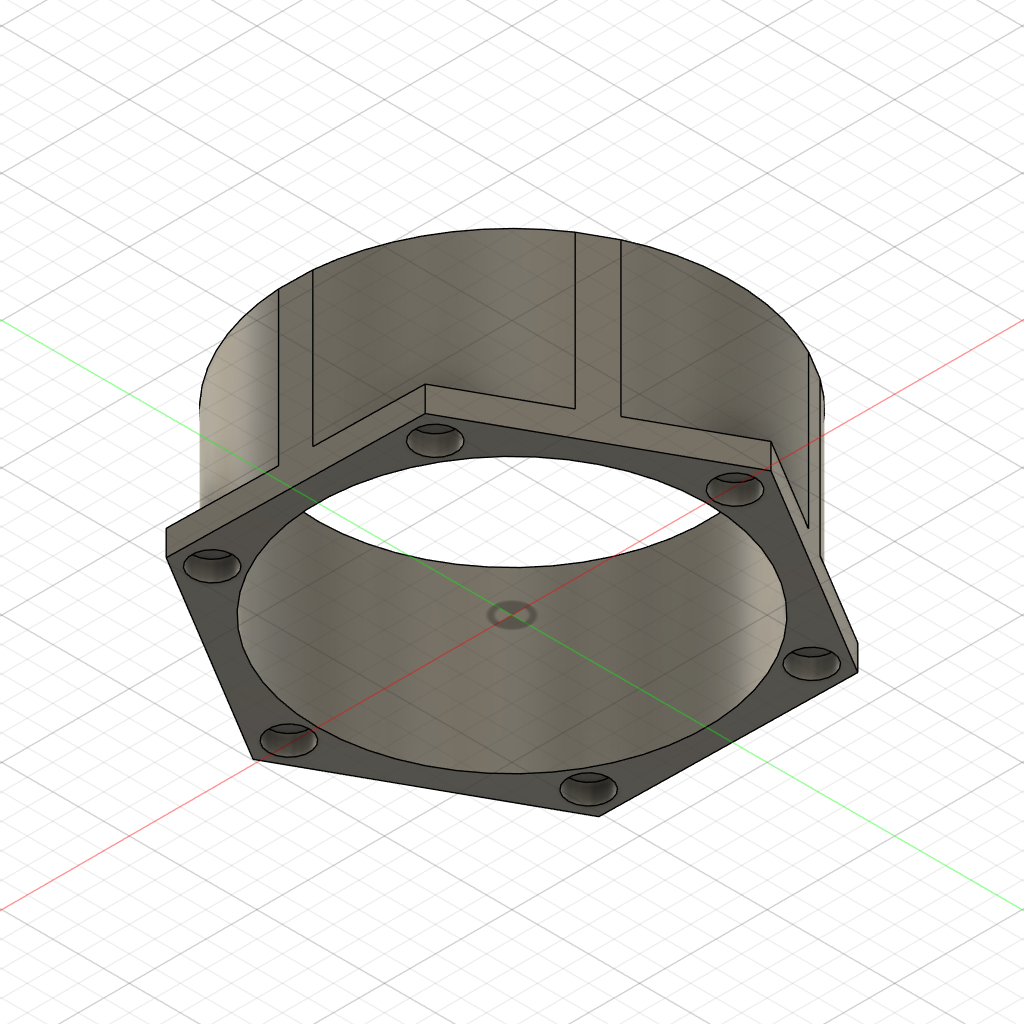

Magnetic Connector

Bayonet Joint

Threaded Joints

Three joint mechanisms were evaluated—magnetic, mechanical interlocks, and a traditional threaded system—each inspired by established joining methods.

Initial Prototyping

The magnet joint will not be ideal for sheer forces that will be common while working in the shop’

Threaded joints require more geometric precision than what a 3D printer can provide without a long calibration process

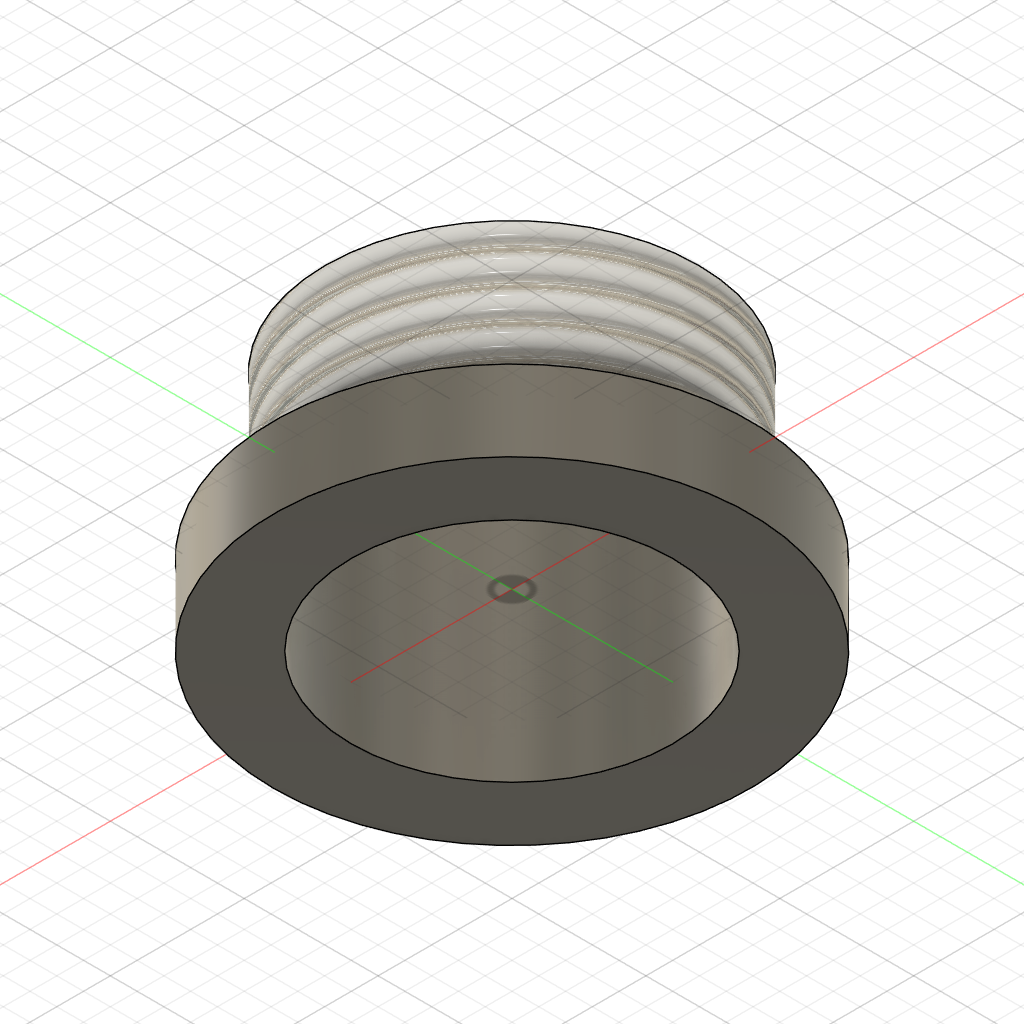

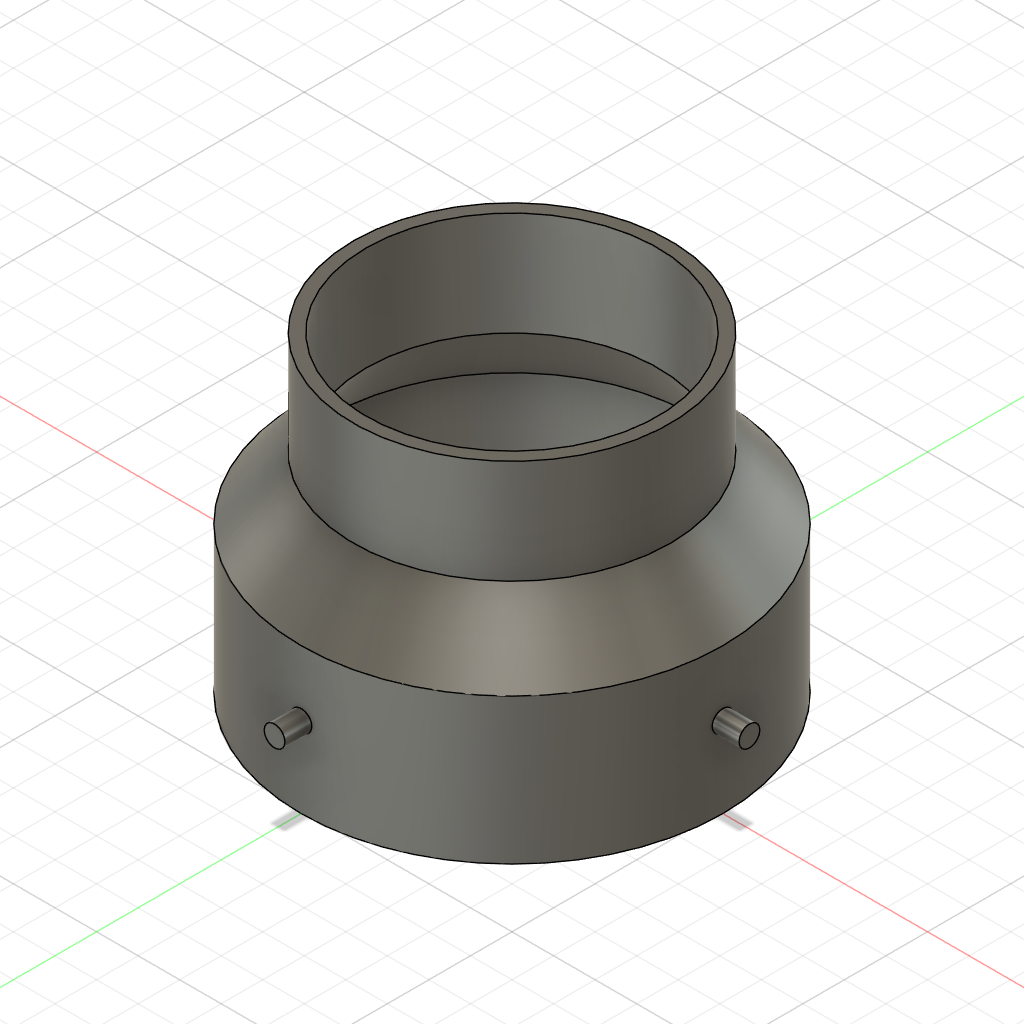

V1

A second layer was added from Version 0 to isolate the joint mechanism from the hose attachment

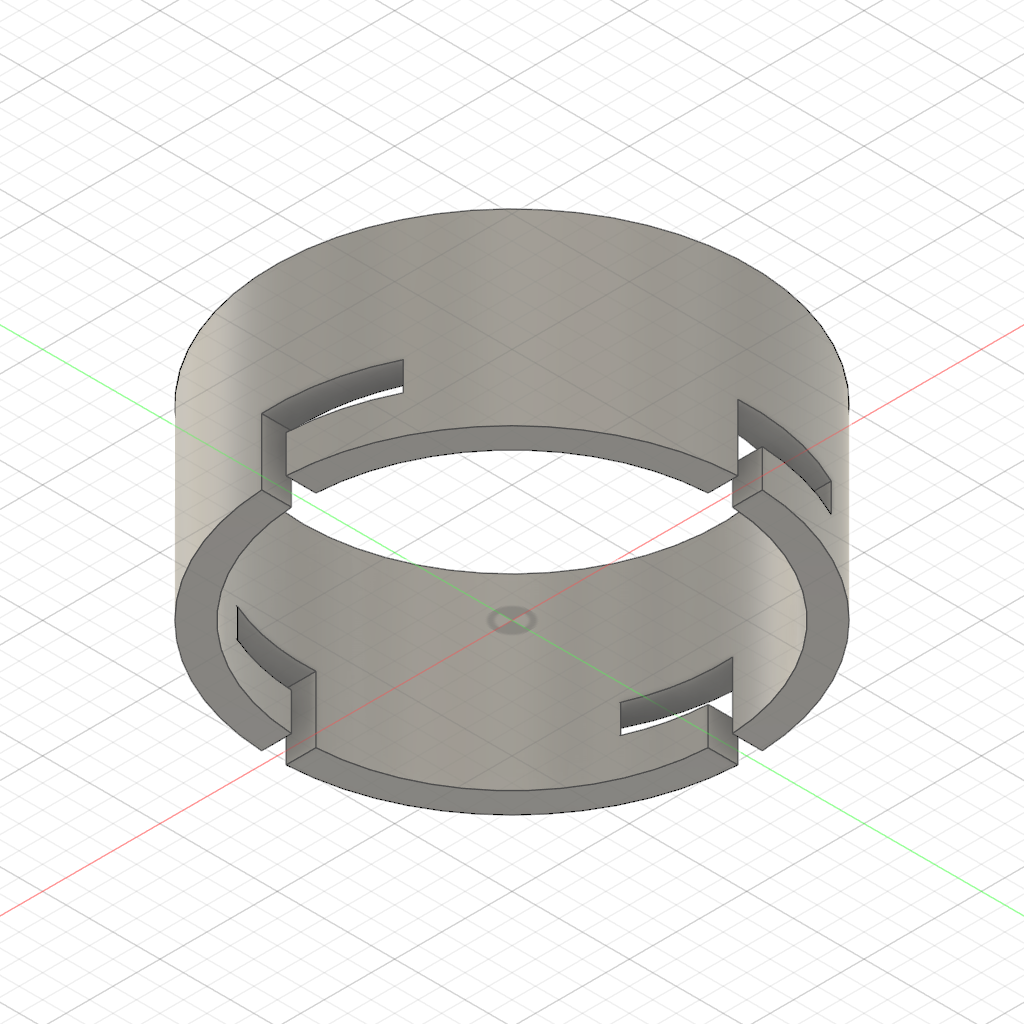

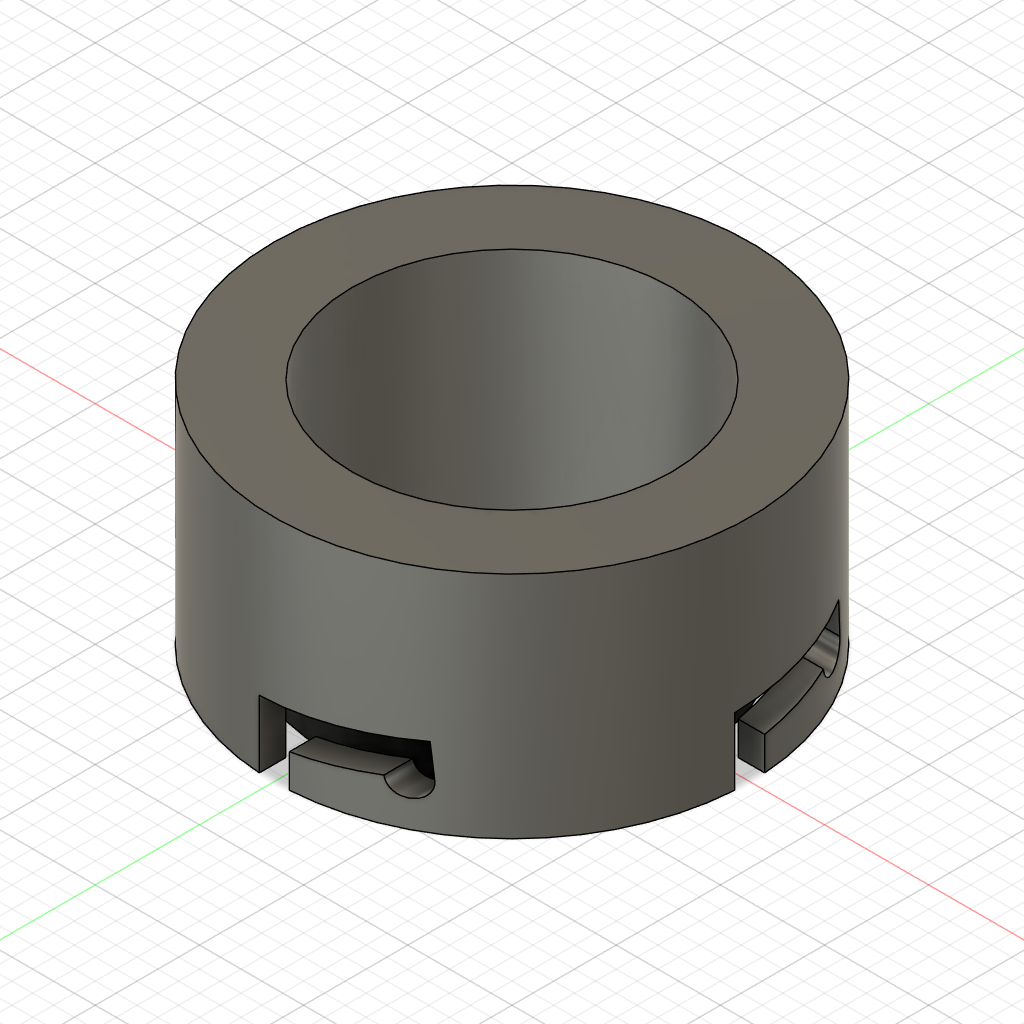

Iteration Testing: Bayonet Joints

V2

The slots for the connection were slanted to strengthen the connection.

The insert part was lofted into the desired diameter for attachment to the hose

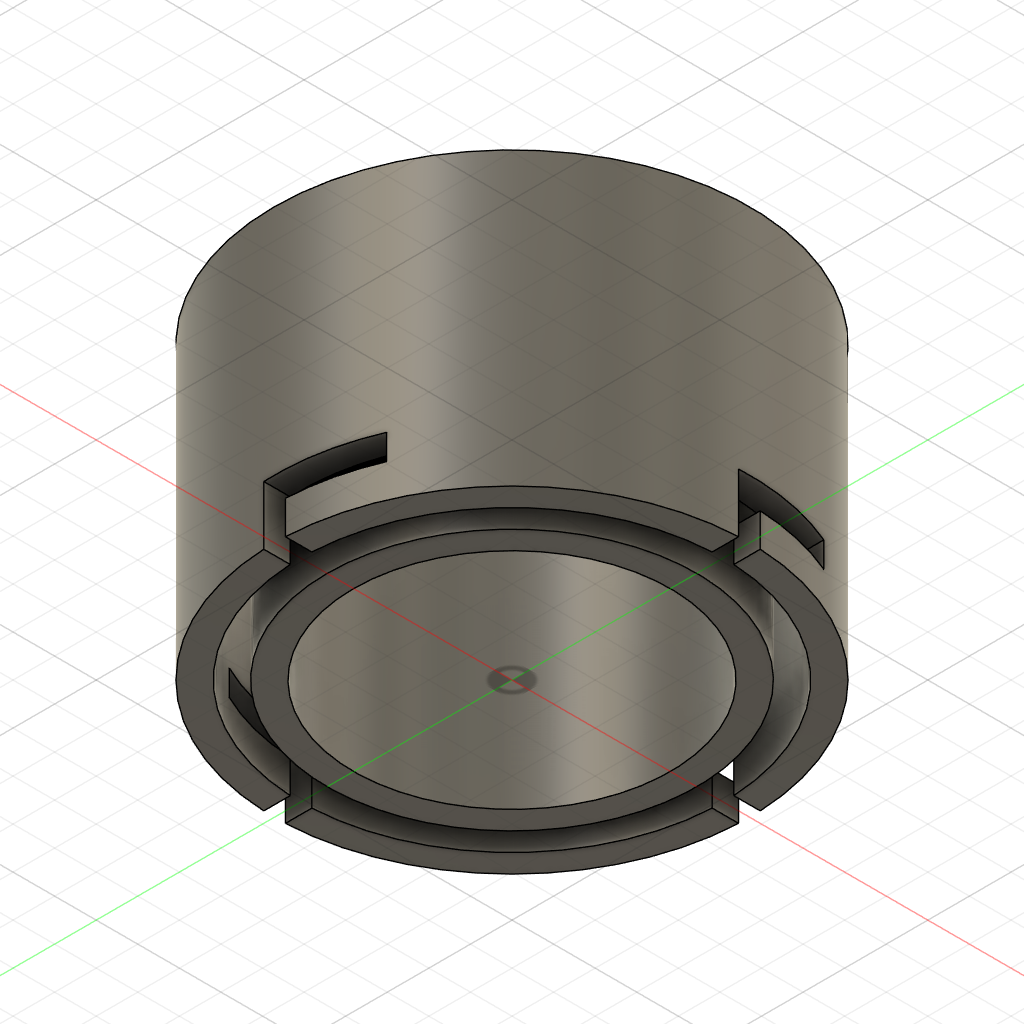

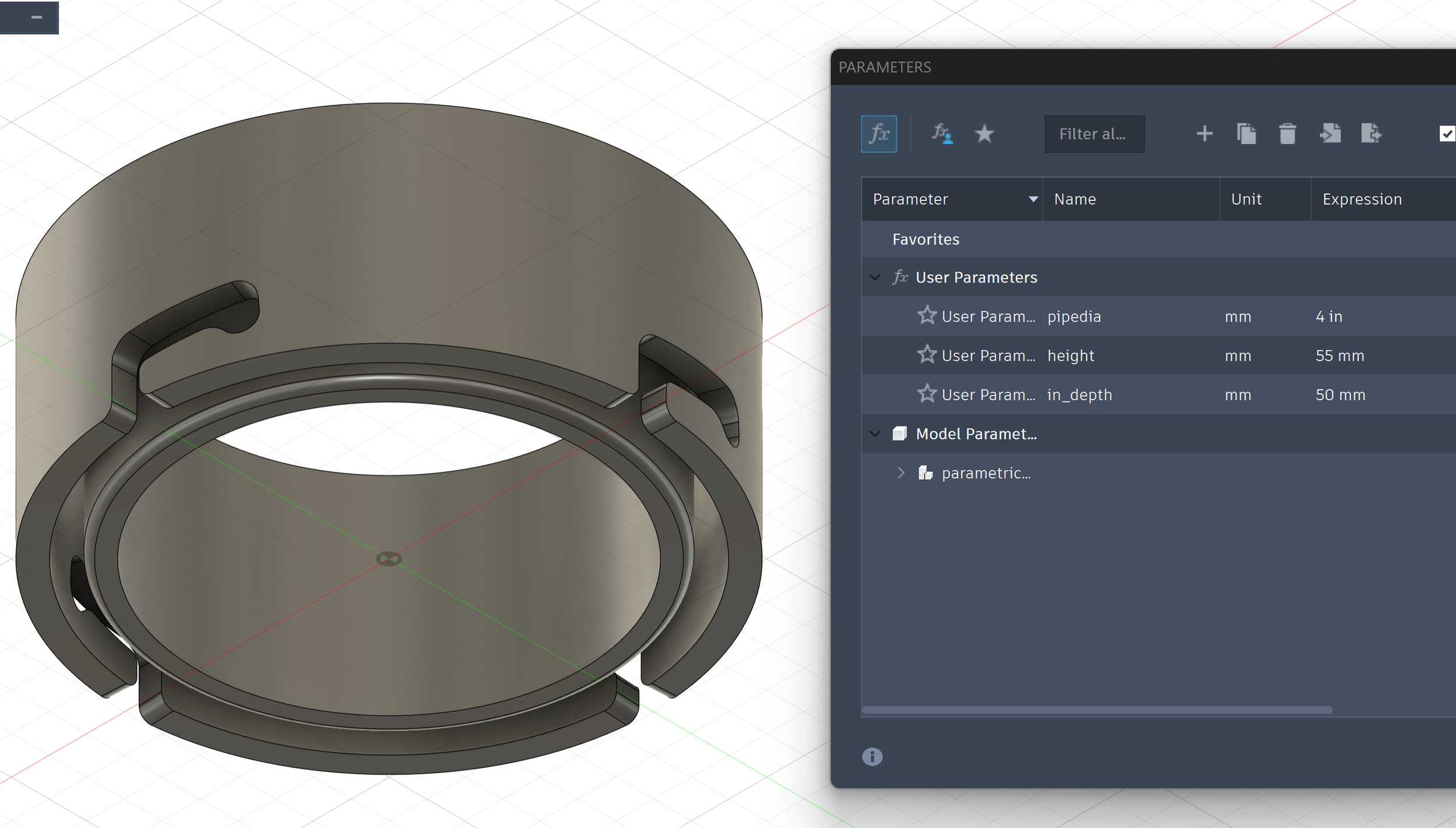

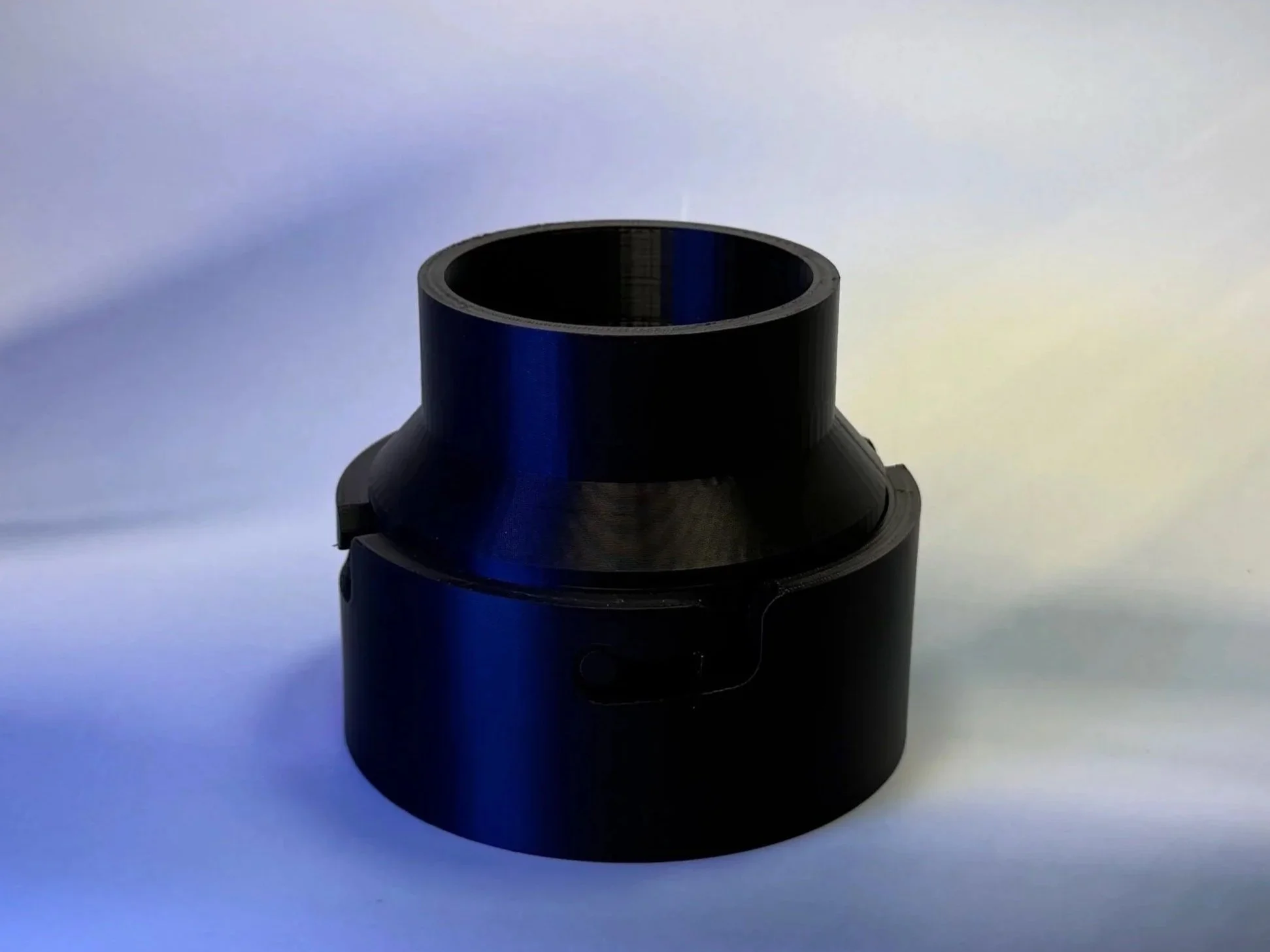

Final Design

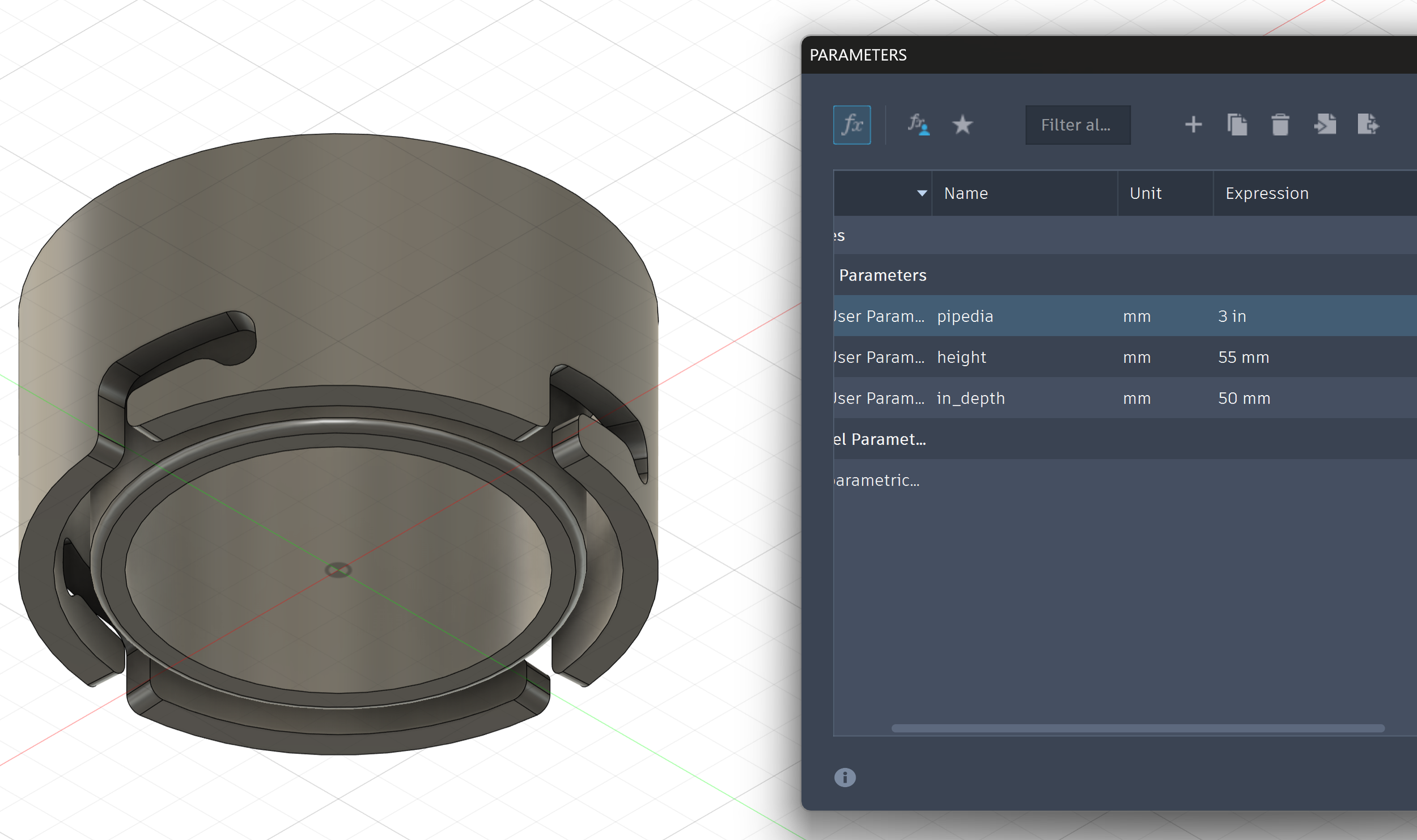

parametrically designed female joint

The parameterized design allows the joint geometry to be easily adapted and reused across a wide range of shop components and fixtures, enabling consistent integration without redesigning the joint for each application.

material selection

Given the common FDM printing materials, ASA is the best choice. However, this means that the tolerance of the fitted part will have to be iteratively be changed to ensure proper fitting between the two locking connectors as well as with the pipe and inlet